Thread tension refers to the amount of pull applied to both the upper and lower threads in an embroidery machine. It plays a crucial role in achieving balanced and perfect stitches. Understanding and properly adjusting thread tension is essential to produce high-quality embroidery projects. Whether you are dealing with bobbin tension issues, tension discs, or the tension gauge, getting the correct tension is vital to ensure consistent, beautiful results.

In this article, we will explore the concept of thread tension in embroidery machines, discuss common reasons for tension problems, and provide tips on how to achieve the ultimate tension for various thread types and embroidery techniques.

With the right knowledge and techniques, you can overcome tension-related challenges and create stunning embroidery designs. So, let’s dive into the world of thread tension and discover how it can make a significant difference in your embroidery work.

Table Of Contents

1. What are the Benefits of Adjusting Thread Tension?

2. Preparing for Thread Tension Adjustment

3. Understanding Your Machine’s Manual/Instructions

4. Types of Embroidery Machines

5. Computerized Embroidery Machines

6. Mechanical Embroidery Machines

7. Overlock, Chain Stitch and Serger Machines

8. Multi-Needle Embroidery Machines

9. Color-Coded Spools of Different Thread Types

10. Conclusion

1. What are the Benefits of Adjusting Thread Tension?

Adjusting thread tension in embroidery machines is crucial for achieving professional and high-quality embroidery projects. Here are some of the key benefits of adjusting thread tension:

1.1 Consistent and Balanced Stitches

Proper thread tension ensures balanced stitches, where the upper and bobbin threads intertwine evenly. This results in clean and precise embroidery designs.

1.2 Reduced Looping and Puckering

Incorrect tension can cause looping of thread underneath the fabric or puckering of the fabric itself. By adjusting the tension, you can prevent these issues, resulting in smooth and flawless embroidery.

1.3 Improved Bobbin Thread Visibility

Adjusting the tension helps in controlling the visibility of the bobbin thread. This is crucial, especially when using contrasting colors, as it ensures that only the intended thread color shows on the surface.

1.4 Minimized Thread Breakage

Loose tension can lead to more embroidery thread breakage, resulting in wasted time and money. Proper tension prevents excessive strain on the thread, reducing breakage and ensuring uninterrupted embroidery workflow.

1.5 Enhanced Overall Efficiency

By adjusting the thread tension, you can optimize the embroidery machine’s performance, allowing for faster machine speeds without compromising the quality of the stitches.

Adjusting thread tension is an essential aspect of embroidery. It ensures high-quality results, minimizes thread breakage, and improves overall efficiency. By achieving proper tension, you can create beautiful and flawless embroidery projects.

2. Preparing for Thread Tension Adjustment

When it comes to achieving high-quality embroidery, proper thread tension is crucial. Thread tension refers to the tension applied to both the upper and bobbin threads as they pass through the machine. In order to get balanced and well-formed stitches, it’s important to have the correct tension. Before making any adjustments to thread tension, it is important to understand the basics of how thread tension works and the common reasons for tension issues. By being aware of these factors and preparing properly, you can ensure a smooth and successful thread tension adjustment process.

3. Understanding Your Machine’s Manual/Instructions for Proper Thread Tension

Proper thread tension is crucial for achieving high-quality embroidery stitches. To ensure the correct tension, it is important to thoroughly understand your embroidery machine’s manual or instructions. This invaluable resource provides specific information about your machine’s tension settings and how to adjust them based on different embroidery projects.

When reviewing your machine’s manual or instructions, pay close attention to the following key components:

1. Thread Path and Tension Discs

2. Bobbin Tension Gauge

3. Upper Thread and White Bobbin Thread

4. Needle and Needle Thread Tension

By thoroughly understanding your embroidery machine’s manual or instructions. You will gain the knowledge and confidence to adjust the thread tension according to the specific requirements of your embroidery projects. This will ultimately allow you to achieve high-quality embroidery with ease and precision.

1. Thread Path and Tension Discs

The thread path and tension discs in an embroidery machine play a crucial role in controlling the tension of the thread. The thread path refers to the designated path that the upper and bobbin threads must follow through the machine. It is important to correctly thread both threads through their respective paths as indicated in the embroidery machine’s manual or instructions.

The tension discs, usually located above the needle area, are an integral part of the thread path. The upper thread passes through these discs, allowing for precise control of the tension. By correctly threading the upper thread through the tension discs, you can achieve consistent tension, resulting in well-balanced stitches.

However, common issues can arise if the thread path or tension discs are not properly attended to. Improper threading can lead to tension issues, causing stitches to be either too loose or too tight. Additionally, buildup of lint in the tension discs can disrupt the smooth flow of the thread, affecting tension control.

To ensure consistent tension, it is important to regularly clean and maintain the tension discs. Cleaning them removes any lint or debris that may have accumulated, allowing for smooth thread flow and optimal tension control.

The thread path and tension discs in an embroidery machine are vital components in achieving proper thread tension control. By understanding their function, addressing common issues, and performing regular cleaning and maintenance. You can ensure consistent and high-quality embroidery results.

2. Bobbin Tension Gauge

A bobbin tension gauge is a tool specifically designed for adjusting thread tension on embroidery machines. Its purpose is to ensure that the bobbin tension is set correctly to achieve optimal stitching results. By using a bobbin tension gauge, you can easily measure and adjust the tension in the bobbin thread.

To ensure proper tension settings for your embroidery machine, follow these steps using a bobbin tension gauge:

1. Begin by removing the bobbin case from the machine and placing it on a flat surface.

2. Insert the bobbin tension gauge into the bobbin case, making sure it is securely seated.

3. Gently pull the bobbin thread through the tension adjustment slot on the bobbin case.

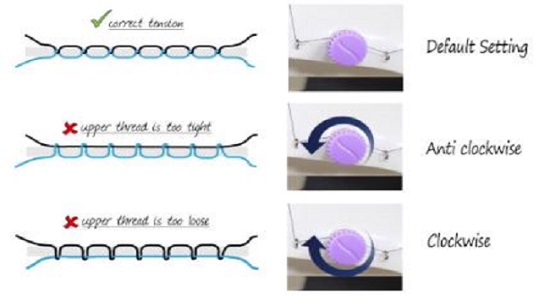

4. Hold the bobbin case and gauge together, and slowly rotate the gauge clockwise to increase tension or counterclockwise to decrease tension.

5. As you rotate the gauge, pay attention to the tension scale on the gauge. Adjust it until the desired tension is reached.

6. Once the tension is set to your preference, remove the bobbin tension gauge from the bobbin case.

7. Reinsert the bobbin case back into the embroidery machine, ensuring that it is securely in place.

By using a bobbin tension gauge and following these steps. You can easily and accurately adjust the tension in the bobbin thread to achieve optimal stitching results for your embroidery projects.

3. Upper Thread and White Bobbin Thread

Achieving proper thread tension is crucial for quality embroidery projects. When it comes to thread tension, both the upper thread and the white bobbin thread play vital roles. These two threads work together to create balanced stitches and ensure the perfect stitch every time.

The upper thread is the thread that runs through the needle of the embroidery machine. It is responsible for creating the visible stitches on the top side of the fabric. The tension of the upper thread needs to be properly adjusted to ensure that it is neither too tight nor too loose.

On the other hand, the white bobbin thread is the thread that runs through the bobbin case underneath the fabric. It forms the stitches on the underside of the fabric. The tension of the bobbin thread should also be balanced with the upper thread to achieve consistent tension throughout the embroidery project.

To ensure the best results, it is recommended to use high-quality thread for both the upper thread and the white bobbin thread. Different thread types may be suitable for different embroidery techniques and fabrics. It is advisable to consult the manufacturer’s recommendations or experiment with different thread types to find the ones that work best for your specific embroidery machine and projects.

By understanding the importance of the upper thread and white bobbin thread and achieving a proper balance between them. You can achieve consistent tension and create high-quality embroidery projects.

4. Needle and Needle Thread Tension

Needle tension plays a crucial role in achieving balanced stitches in embroidery projects. It refers to the tension of the upper thread in the needle of the embroidery machine. Maintaining the correct needle tension is essential for creating perfect stitches and avoiding issues such as thread breakage or loops on the underside of the fabric.

When working on small lettering or intricate designs, it is recommended to loosen the needle tension slightly to allow the stitches to form properly. On the other hand, for long stitches or when using thicker threads. Tightening the needle tension can help prevent loose or uneven stitches.

Machine speed also affects needle tension. High-speed embroidery may require a slightly tighter needle tension to compensate for the increased thread movement and prevent thread breakage. Conversely, reducing the machine speed may require a slight adjustment to loosen the needle tension.

Certain stitch types, such as satin stitches or column stitches, may require specific needle tension adjustments. Satin stitches often benefit from a slightly looser needle tension to ensure smooth and neat edges. While column stitches may require a tighter needle tension to prevent gaps between stitches.

Experimenting with different thread tensions and techniques is key to finding the perfect balance for your embroidery projects. It is important to remember that each embroidery machine may have slightly different tension settings. So it is advisable to consult your machine’s manual for specific instructions on adjusting needle tension.

4. Types of Embroidery Machines

Embroidery machines come in various types, each suitable for different embroidery projects and skill levels. There are three main types of embroidery machines:

1. Domestic/hobby Embroidery Machines

2. Commercial Embroidery Machines

3. Industrial Embroidery Machines

1. Domestic/hobby Embroidery Machines

Domestic/hobby machines are designed for personal use and are often smaller and more affordable than other types. These machines usually have a limited number of built-in designs and stitch options. But these embroidery machines are perfect for beginners or those who want to embroider as a hobby.

2. Commercial Embroidery Machines

Commercial machines are more advanced and are used by small businesses or professional embroiderers. They offer a wider range of stitch options, larger embroidery areas, and the ability to upload custom designs. These embroidery machines are ideal for medium-scale embroidery projects.

3. Industrial Embroidery Machines

Industrial machines are the most powerful and are used for high-volume and heavy-duty embroidery work. They are capable of embroidering on a wide variety of materials and can handle continuous operation. These machines are commonly found in large-scale embroidery businesses and garment industries.

In addition to these main categories, there are also multi-needle machines that can hold multiple thread colors at once, making color changes more efficient. Computerized embroidery machines with touchscreens and USB connectivity allow for easy design customization and faster embroidery. Ultimately, the type of embroidery machine chosen depends on the scale of the embroidery projects, skill level, and specific requirements of the embroiderer.

5. Computerized Embroidery Machines

Computerized embroidery machines offer a range of features and functionalities that make them a popular choice for embroidery enthusiasts and professionals alike. These machines use computer technology to create intricate embroidery designs with precision and ease.

One of the key features of computerized embroidery machines is their ability to create complex designs. With a vast library of built-in designs and the option to upload custom designs, these machines allow users to create unique and detailed embroidery projects. Additionally, these machines often have automatic thread trimming and tension adjustment features, ensuring a clean and professional finish.

Another benefit of computerized embroidery machines is their efficiency. These machines can stitch at a much faster speed compared to traditional embroidery methods, saving both time and effort. Additionally, their precise stitching capabilities ensure that every stitch is accurate and consistent.

Computerized embroidery machines also offer the convenience of saving and editing designs. Users can easily store their favorite designs in the machine’s memory and make adjustments as needed. This flexibility allows for greater creativity and experimentation with different embroidery patterns and colors.

Computerized embroidery machines offer a range of features and benefits that make them an excellent choice for embroidery enthusiasts and professionals. With their embroidery libraries, precise stitching capabilities, and convenience, these machines provide a convenient and efficient way to create stunning embroidery projects.

6. Mechanical Embroidery Machines

Mechanical embroidery machines are a type of embroidery machine that uses mechanical components to create intricate designs on fabric. These machines are known for their reliability and durability, making them a popular choice among professional embroiderers.

One of the key features of mechanical embroidery machines is their ability to create intricate and detailed designs. These machines often come with a wide range of built-in decorative stitches and patterns. Allowing users to easily create unique and personalized embroidery projects. Additionally, mechanical embroidery machines typically have adjustable stitch length and width settings, giving users greater control over the final result.

Mechanical embroidery machines work by using a combination of mechanical parts, such as gears and levers, to move the fabric and control the needle. This mechanical operation ensures accurate and precise stitching, resulting in high-quality embroidery. Another advantage of mechanical embroidery machines is their ability to handle heavy-duty fabrics and thick layers. Making them suitable for a wide range of projects.

While mechanical embroidery machines offer numerous advantages, they do have some disadvantages. One of the main drawbacks is their limited stitching options compared to computerized embroidery machines. Mechanical machines typically have a set number of built-in stitches and patterns. Which may limit the creativity and versatility of certain embroidery projects. Additionally, mechanical machines can be more challenging to operate, requiring manual adjustment of settings and relying on the user’s skill and experience.

Mechanical embroidery machines are reliable and durable tools that offer the ability to create intricate and detailed embroidery designs. While they may have limitations in terms of stitching options and ease of use, they remain a popular choice for professional embroiderers due to their reliability and handling of heavy-duty fabrics.

7. Overlock, Chain Stitch and Serger Machines

Overlock, chain stitch, and serger machines are three popular types of embroidery machines that offer unique features and functionalities to enhance the embroidery experience.

These machines also known as sergers, are specifically designed to create professional-looking edge finishes on fabric. They use multiple threads to sew, trim, and finish the edges simultaneously, resulting in secure and neat seams.

Chain Stitch machines, on the other hand, use a single thread to create a chain-like stitch, with each loop interconnecting with the previously formed loop. This type of machine is commonly used for decorative stitching, such as adding borders or creating delicate patterns.

Serger machines, as the name suggests, combine the functionalities of both overlock and chain stitch machines. They are capable of creating strong seams with a neat finish by using multiple threads. Additionally, sergers have the ability to trim excess fabric while sewing, saving time and effort.

The main benefit of overlock machines is their ability to create professional-looking edge finishes quickly and efficiently. They are commonly used in garment construction and are particularly useful for sewing stretchy fabrics. Chain Stitch machines, on the other hand, excel in creating decorative stitches, adding intricate details to embroidery projects. Serger machines offer the best of both worlds, providing secure seams with a professional finish, along with the option for decorative stitching.

However, it’s important to note that each type of machine also has its limitations. Overlock embroidery machines may not offer a wide range of decorative stitching options compared to other embroidery machines. Chain Stitch machines, while great for decorative stitching, may not be suitable for heavy-duty sewing. Serger machines, although versatile, may require some practice to master their various functions.

8. Multi-Needle Embroidery Machines

Multi-needle embroidery machines are a game-changer when it comes to complex embroidery projects. Unlike single-needle machines, multi-needle machines have multiple needles that can be threaded with different thread colors simultaneously. This allows for the creation of intricate designs and patterns with ease.

The main benefit of using a multi-needle machine is the increased efficiency it provides. With multiple needles, you can embroider different areas of your project simultaneously, saving time and effort. This is especially useful when working on large or intricate designs that would take a significant amount of time with a single-needle machine.

Another advantage of multi-needle machines is the ability to use multiple thread colors. This opens up endless possibilities for creative embroidery projects. Whether you’re looking to add depth and dimension to your designs or replicate intricate images with exact color matching. A multi-needle machine can make it happen.

In addition to efficiency and versatility, multi-needle machines also offer features like automatic thread cutting and built-in design libraries, further streamlining the embroidery process. These machines are perfect for professionals or hobbyists who want to take their embroidery skills to the next level.

Multi-needle embroidery machines are a must-have for those tackling complex embroidery projects. They offer increased efficiency, the ability to use multiple thread colors simultaneously, and the opportunity to create intricate and stunning designs. Upgrade to a multi-needle machine and watch your embroidery skills soar to new heights.

9. Color-Coded Spools of Different Thread Types

To ensure the best results in your embroidery projects, it is important to use color-coded spools of different thread types in your embroidery machine. This simple practice can have a big impact on achieving balanced stitches and preventing tension issues.

Each thread type has its own unique properties, such as thickness and surface texture. By using the correct thread type for each part of your project. You can ensure that your stitches are consistent and uniform. For example, using a finer thread for delicate details and a thicker thread for outlines or filling can help create a dimensional and visually appealing design.

Common thread types used in embroidery projects include polyester, rayon, cotton, metallic, and nylon. Polyester and rayon threads are popular choices due to their vibrant colors and durability. Cotton threads are often used for a more natural and textured look, while metallic threads can add a touch of sparkle to your designs. Nylon threads, on the other hand, are strong and resistant, making them ideal for embroidery on heavy fabrics.

Furthermore, using multiple thread colors can also create visual effects in your designs. By choosing complementary or contrasting colors, you can add depth and dimension to your embroidery. Experimenting with thread colors can enhance the overall aesthetic of your projects and make them stand out.

Using color-coded spools of different thread types is essential for achieving balanced stitches, preventing tension issues, and creating visual effects in your embroidery projects. By understanding the properties of each thread type and experimenting with different colors. You can elevate your embroidery to new levels of artistry and creativity.

10. Conclusion

In conclusion, mastering thread tension is a fundamental skill for achieving outstanding embroidery results. Properly adjusted tension leads to balanced, flawless stitches and reduces common issues like looping, puckering, and thread breakage. It also improves visibility of the bobbin thread and enhances overall efficiency in the embroidery process.

With the right knowledge and techniques, you can conquer thread tension challenges and create stunning embroidery designs. For professional embroidery digitizing services to take your projects to the next level. Visit our website and elevate your embroidery work to new heights.

FAQs (Frequently Asked Questions)

Q1. Why is adjusting thread tension important in embroidery machines?

Adjusting thread tension is crucial to achieve balanced stitches and high-quality embroidery results. It ensures consistent, clean, and precise designs, reduces issues like looping and puckering, and minimizes thread breakage.

Q2. What are the three main types of embroidery machines?

The three main types of embroidery machines are domestic/hobby machines (for personal use and beginners), commercial machines (for small businesses and professionals), and industrial machines (for heavy-duty and large-scale work).

Q3. What advantages do computerized embroidery machines offer over traditional methods?

Computerized embroidery machines provide the ability to create complex designs, work at faster speeds, and offer features like automatic thread trimming and design customization, making embroidery easier and more efficient.

Q4. What are the key benefits of using multi-needle embroidery machines?

Multi-needle embroidery machines offer increased efficiency, the ability to use multiple thread colors simultaneously, and the opportunity to create intricate and stunning designs, making them ideal for complex embroidery projects.

Q5. Why is it important to understand your embroidery machine’s manual for proper thread tension adjustment?

Understanding the machine’s manual is essential to correctly adjust thread tension, as it provides information about thread paths, tension discs, bobbin tension, upper thread tension, and needle tension specific to your machine, ensuring high-quality results.