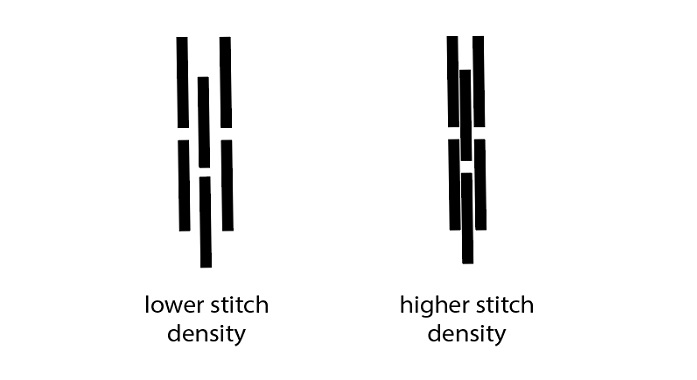

Embroidery enthusiasts understand the crucial role that stitch density plays in achieving impeccable embroidery designs. But what exactly is stitch density? In the realm of machine embroidery, stitch density refers to the number of stitches per unit area within a design. Essentially, it determines how closely together the stitches are placed, influencing the overall appearance, durability, and quality of the embroidery.

The Basics of Machine Embroidery

Before delving into stitch density, let’s revisit the fundamentals of machine embroidery. This intricate craft involves stitching decorative designs onto various fabrics using specialized embroidery machines. Each design is composed of a series of stitches, carefully programmed into the machine to create intricate patterns, textures, and shapes. Stitch density is a critical factor in ensuring that these designs translate seamlessly onto the chosen fabric, maintaining both visual appeal and structural integrity.

How Stitch Density is Measured

Measuring stitch density involves calculating the number of stitches within a specific area of the embroidery design. This is typically expressed as stitches per inch (SPI) or stitches per centimeter (SPC), depending on the unit of measurement preferred. By quantifying the stitch density, embroiderers can effectively gauge the level of detail and intricacy within their designs, allowing for precise adjustments to achieve desired results.

Factors Affecting Stitch Density

Several factors influence stitch density, including the type of fabric being embroidered, the thread type and weight used, and the complexity of the design. Different embroidery fabrics may require varying levels of stitch density to ensure optimal results, with denser fabrics often necessitating a higher stitch count to penetrate effectively. Similarly, the choice of thread and its weight can impact stitch density, as thicker threads may require adjustments to prevent overcrowding or tension issues within the design. Additionally, complex designs with intricate details may require higher stitch density to accurately capture fine lines and textures.

Importance of Proper Stitch Density

Achieving the ideal stitch density is paramount for producing high-quality embroidery. The stitch density directly influences the appearance, durability, and longevity of the embroidery design. Insufficient stitch density can result in gaps or distortion within the design, compromising its overall quality. Conversely, excessive stitch density may lead to puckering or stiffness, detracting from the aesthetic appeal of the embroidery. By maintaining proper stitch density, embroiderers can ensure that their designs retain crispness, clarity, and durability over time.

Achieving Ideal Stitch Density

To achieve optimal stitch density, it is essential to consider various factors, including adjusting machine settings, selecting the appropriate needle and thread, and employing proper hooping techniques. Fine-tuning these elements allows embroiderers to control the density of stitches within their designs, ensuring consistent and precise results. Experimenting with different settings and materials can help determine the optimal combination for achieving desired stitch density while maintaining design integrity.

Techniques for Improving Stitch Density

Several techniques can be employed to enhance stitch density and improve the quality of embroidery designs. One such technique is the use of underlay stitches, which provide a stable foundation for subsequent layers of stitches, resulting in smoother, more even coverage. Additionally, proper hooping techniques, such as using stabilizers and ensuring tautness, can help prevent fabric distortion and maintain optimal stitch density throughout the embroidery process.

Stitch Density in Different Types of Designs

Different types of embroidery designs require varying levels of stitch density to achieve optimal results. Satin stitch designs, characterized by smooth, continuous lines, often require higher stitch density to ensure seamless coverage and prevent fabric show-through. Fill stitch designs, on the other hand, may require lower stitch density to allow for more open spaces and textured effects. Complex designs with various stitch types may necessitate a combination of stitch densities to capture intricate details while maintaining overall cohesion.

Common Stitch Density Problems and Solutions

Despite careful planning and execution, embroiderers may encounter common stitch density problems such as puckering, gaps in embroidery, or uneven stitching. These issues can often be addressed through adjustments to machine settings, thread tension, or digitizing techniques. Conducting stitch density tests and making incremental adjustments can help troubleshoot and resolve such issues, ensuring consistent quality across embroidery projects.

Importance of Testing Stitch Density

Testing stitch density is an essential step in the embroidery process, allowing embroiderers to assess the impact of different settings and materials on the final result. By conducting stitch density tests on sample fabrics, embroiderers can identify the optimal combination of settings and materials for achieving desired results. Minimizing the risk of errors or inconsistencies in the final embroidery design.

Understanding Digitizing and Stitch Density

Digitizing plays a crucial role in determining stitch density, as digitizers translate artwork or designs into digital instructions that the embroidery machine can interpret. Communicating stitch density requirements to digitizers is essential for ensuring that the digitized design accurately reflects the desired stitch density and overall appearance of the embroidery. Clear communication and collaboration between embroiderers and digitizers are key to achieving optimal results.

How to Interpret Stitch Density Information in Embroidery Designs

Interpreting stitch density information in embroidery designs involves understanding design specifications and communicating effectively with digitizers and machine operators. By familiarizing themselves with stitch density terminology and techniques, embroiderers can effectively convey their preferences and requirements to ensure that the final embroidery design meets their expectations.

Advanced Stitch Density Techniques

Advanced stitch density techniques allow embroiderers to elevate their designs and create visually stunning embroidery projects. Layering stitches for texture, creating dimension with varying stitch densities, and incorporating innovative techniques can add depth and complexity to embroidery designs, resulting in truly unique and memorable creations.

The Future of Stitch Density in Machine Embroidery

As technology continues to advance, the future of stitch density in machine embroidery holds exciting possibilities. Advancements in machine technology, materials, and digitizing software are poised to revolutionize the embroidery industry, offering embroiderers unprecedented control and creativity in achieving stitch density and design outcomes. Keeping abreast of emerging trends and embracing innovation will be key to staying at the forefront of machine embroidery.

Conclusion

In conclusion, mastering stitch density is essential for achieving exceptional results in machine embroidery. By understanding the fundamentals of stitch density, experimenting with techniques, and staying informed about advancements in the field, embroiderers can elevate their craft and create stunning embroidery designs that captivate and inspire. With patience, practice, and a commitment to excellence, mastering stitch density opens up a world of creative possibilities in machine embroidery. Ready to elevate your style or brand? Explore our embroidery services today!

FAQs (Frequently Asked Questions)

Q1. What is stitch density in machine embroidery?

Stitch density in machine embroidery refers to the number of stitches per unit area within a design. It determines how closely together stitches are placed, affecting the overall appearance and quality of the embroidery.

Q2. How is stitch density measured in embroidery?

Stitch density is typically measured as stitches per inch (SPI) or stitches per centimeter (SPC). It involves calculating the number of stitches within a specific area of the embroidery design.

Q3. What factors influence stitch density?

Several factors affect stitch density, including the type of fabric, thread type and weight, and complexity of the design. Different fabrics and thread types may require varying levels of stitch density to achieve optimal results.

Q4. Why is achieving proper stitch density important?

Proper stitch density is crucial for producing high-quality embroidery. It directly influences the appearance, durability, and longevity of the design. Insufficient or excessive stitch density can result in distortions or issues within the embroidery.

Q5. What techniques can be used to improve stitch density?

Techniques such as using underlay stitches for stability, employing proper hooping techniques, and adjusting machine settings can enhance stitch density. Experimenting with different techniques and materials can help achieve optimal results in embroidery projects.