Embroidery digitizing is a craft that seamlessly blends technology with traditional craftsmanship. In the realm of textile design, it holds immense significance, as it transforms intricate designs into digital formats that embroidery machines can understand. However, ensuring quality control in embroidery digitizing is essential to guarantee that the final embroidered product matches the original design’s intricacy and beauty. Here, we delve into the art of maintaining quality control in embroidery digitizing, exploring the steps and considerations necessary for achieving exceptional results.

Understanding the Basics:

Before diving into the intricacies of quality control in embroidery, it’s crucial to grasp the fundamentals of embroidery digitizing. Essentially, this process involves converting artwork or designs into a digital format using specialized software. These digital files, typically in formats like .dst or .emb, contain instructions for the embroidery machine, dictating stitch types, densities, and colors.

Factors Affecting Quality Control in Embroidery:

Several factors can influence the quality of embroidery digitizing, including:

Artwork Complexity:

Complex designs with intricate details pose unique challenges in digitization. Each element of the artwork must be carefully translated into stitches while maintaining clarity and definition. Meticulous attention to detail is required to ensure that every fine line, curve, and texture is accurately represented in the digital format. Failure to capture the intricacies of the original artwork can result in loss of detail and compromised visual appeal in the embroidered piece.

Stitch Types and Densities:

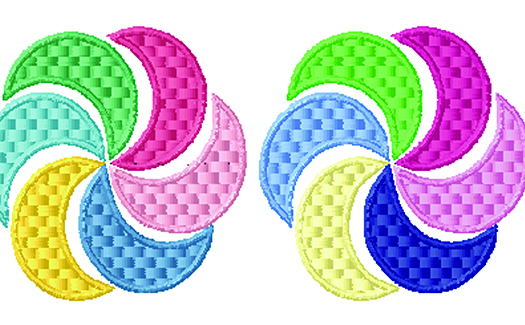

Different areas of a design may require varying stitch types and densities to achieve the desired visual effect. For example, areas with solid colors or intricate details may necessitate higher stitch densities to ensure full coverage and definition. On the other hand, areas with smooth gradients or delicate textures may benefit from lighter stitch densities to maintain a soft, nuanced appearance. Selecting the appropriate stitch types and densities is crucial for preserving the design’s integrity and achieving optimal embroidery results.

Thread Colors and Variations:

The selection of thread colors is paramount in accurately representing the original artwork. Matching the colors of the digital design to the desired thread shades requires careful consideration of factors such as hue, saturation, and brightness. Additionally, managing thread variations and gradients effectively is essential for achieving seamless transitions and subtle shading in the embroidered piece. Proper color management ensures that the final embroidery closely resembles the original artwork in both color accuracy and vibrancy.

Fabric Type and Texture:

The type and texture of the fabric onto which the design will be embroidered significantly influence digitizing parameters. Factors such as fabric stretchiness, density, and surface texture affect stitch placement, tension settings, and overall embroidery quality. For example, stretchy fabrics like spandex may require special digitizing techniques to prevent distortion, while dense fabrics like denim may necessitate adjustments to stitch densities for optimal coverage. Understanding the characteristics of the fabric is essential for tailoring the digitizing process to achieve the best results on a particular substrate.

Machine Capabilities:

Each embroidery machine comes with its own set of capabilities and limitations that must be taken into account during digitizing. Factors such as maximum stitch counts, hoop sizes, and speed settings vary between machines and can impact the complexity and size of the designs that can be embroidered. Understanding the capabilities of the embroidery machine enables digitizers to optimize the digitizing process for efficient production and high-quality results. It also allows them to explore creative possibilities within the constraints of the machine’s capabilities, pushing the boundaries of what can be achieved in embroidery digitizing.

Steps to Maintain Quality Control in Embroidery:

Achieving consistent quality control in embroidery digitizing requires a systematic approach and attention to detail. Here are the essential steps to ensure quality control in embroidery:

1. Start with High-Quality Artwork:

The digitizing process begins with the artwork. Using high-resolution, clear artwork as a starting point ensures that the digitized design accurately reflects the original intent of the artist or designer. Clear artwork provides a solid foundation for precise digitization, reducing the likelihood of errors or discrepancies in the final embroidery.

2. Choose the Right Software:

Investing in reputable embroidery digitizing software is crucial for achieving quality results. Advanced software offers a range of features and customization options that allow digitizers to accurately translate artwork into digital embroidery files. Familiarizing oneself with the software’s capabilities is essential to fully leverage its potential and produce high-quality digitized designs.

3. Conduct Test Stitch-Outs:

Before proceeding with the final embroidery, it’s essential to conduct test stitch-outs on similar fabric to evaluate the digitized design’s appearance and quality. Test stitch-outs help identify any issues or areas for improvement, allowing for adjustments to be made before the final production run. This iterative process ensures that the digitized design is optimized for the intended fabric and thread, minimizing the risk of errors in the final embroidery.

4. Optimize Stitch Settings:

Fine-tuning stitch settings is critical for achieving optimal embroidery results. Adjusting parameters such as stitch type, length, density, and underlay helps enhance clarity, definition, and overall quality control in embroidery. Paying close attention to areas of intricate detail or color transitions ensures that the digitized design accurately captures the nuances of the original artwork.

5. Color Matching and Sequencing:

Accurate color matching is essential for producing embroidery that faithfully represents the original artwork. Referencing standardized color charts or swatches helps ensure consistency and precision in color selection. Organizing the design’s color sequence logically minimizes thread changes and optimizes production efficiency, resulting in a cohesive and visually appealing embroidered piece.

6. Quality Control in Embroidery Assurance Checks:

Implementing thorough quality assurance checks throughout the digitizing process is crucial for identifying and addressing any errors or inconsistencies. Meticulously reviewing the digital design helps ensure accuracy and quality before finalizing it for embroidery. Regular quality control in embroidery checks help maintain consistency and uphold high standards throughout the digitizing process.

7. Collaborate with Embroidery Professionals:

Collaborating with experienced embroidery professionals provides valuable insights and feedback on digitized designs. Their expertise can help identify areas for improvement and offer suggestions for optimizing quality and efficiency. Working closely with embroidery professionals fosters a collaborative environment focused on achieving the best possible results.

8. Document and Iterate:

Keeping detailed records of digitizing parameters, test stitch-outs, and feedback received during the quality control in embroidery process is essential for continuous improvement. Documenting successes and lessons learned enables digitizers to iteratively refine and enhance their techniques over time. By documenting and iterating on the digitizing process, embroiderers can consistently maintain high-quality standards and deliver exceptional results.

Conclusion

By following these steps and considerations, you can maintain rigorous quality control in embroidery digitizing, ensuring that each embroidered piece reflects the original artwork’s beauty and intricacy. With dedication, practice, and attention to detail, mastering the art of embroidery digitizing can lead to consistently stunning results that delight both creators and customers alike.