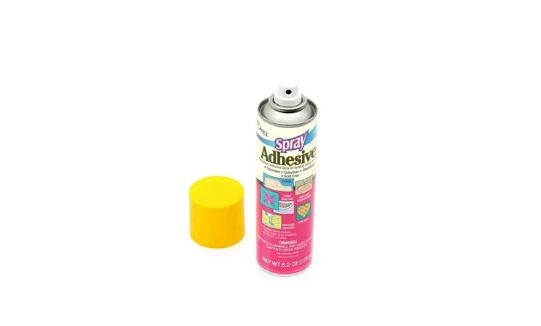

Embroidery spray adhesive is a type of adhesive that is specifically designed for use in embroidery projects. It is a temporary adhesive that can be applied to fabric pieces to hold them in place while they are being embroidered. This spray adhesive creates a temporary bond that keeps the fabric secure. Allowing for easier stitching and precise positioning of applique pieces. Embroidery spray adhesive is also commonly used for machine embroidery projects to prevent shifting or puckering of the fabric. It is available in a wide range of brands and varieties, each offering different bond strengths and application methods. When using embroidery spray adhesive, it is important to use it in a well-ventilated area and follow the manufacturer’s instructions for best results.

After the embroidery is complete, the adhesive can usually be easily removed by gently rubbing it with a dry cloth or washing the fabric. Overall, embroidery spray adhesive is a useful tool for any embroidery enthusiast and can greatly enhance the ease and accuracy of their projects.

Table Of Contents

Benefits of Using an Embroidery Spray Adhesive

Types of Embroidery Spray Adhesives

Preparing your Work Area for Applying the Adhesive

Ensuring You Have a Well-Ventilated Area

Selecting the Right Type of Embroidery Spray Adhesive

Application of the Adhesive

Conclusion

Benefits of Using an Embroidery Spray Adhesive

Embroidery spray adhesive offers a wide range of benefits for machine embroidery projects. It is a temporary spray adhesive that secures fabric in place, allowing for easy repositioning as needed. This adhesive is specifically designed to keep fabric taut, reducing hoop marks and ensuring improved stitch quality.

One of the main advantages of using embroidery spray adhesive is its versatility. It can be used in various applications such as applying embroidery backing. Securing fabric during applique, holding fabric for quilting, and for temporary fabric bonding. It is especially useful when working with delicate or slippery fabrics that tend to shift or move during embroidery.

By using an embroidery spray adhesive, you can ensure that your fabric pieces stay in place and do not shift or wrinkle while sewing. This significantly improves the accuracy and precision of your embroidery design. Additionally, embroidery spray adhesive provides a temporary bond that can be easily removed or repositioned without leaving any residue on the fabric.

When using embroidery spray adhesive, it is important to follow the manufacturer’s instructions. It is recommended to use it in a well-ventilated area and apply it evenly on the fabric background. It is also advisable to test the adhesive on a small piece of fabric before applying it to the entire project.

Types of Embroidery Spray Adhesives

Embroidery spray adhesives come in various types, each designed for specific applications and preferences.

One common type is the temporary spray adhesive, which is ideal for securing fabric during applique or quilting. This type of adhesive provides a temporary bond that can be easily removed or repositioned without damaging the fabric.

Another type is the permanent spray adhesive, which creates a strong bond between fabric pieces. It is suitable for machine embroidery projects that require long-lasting durability.

There are also different formulations of embroidery spray adhesive, including those that are chlorinated solvent-based or made with mineral spirits. These options offer a wide range of bond strengths and can be chosen based on the type of fabric being used. Whether it’s a delicate silk or a heavy denim, there is an embroidery spray adhesive that can meet your needs. It is essential to read the instructions and test the adhesive on a small fabric piece. Before applying it to the entire project to ensure compatibility and desired results. Overall, having the right type of embroidery spray adhesive can greatly enhance the quality and precision of your embroidery work.

1. Chlorinated Solvents

Chlorinated solvents are commonly used in embroidery spray adhesives due to their strong bond strength and wide range of applications. These solvents, such as trichloroethylene, methylene chloride, and perchloroethylene, provide excellent temporary bonding for embroidery projects.

One of the key advantages of using chlorinated solvents as embroidery spray adhesives is their ability to create a strong bond. Between fabric pieces and other materials, such as applique pieces or cardboard boxes. This bond ensures that the embroidered design stays in place throughout the sewing process and even after multiple washes.

Another benefit of chlorinated solvents is their versatility. They can be used on a variety of fabrics, making them suitable for different types of embroidery designs. Whether you are working with delicate materials or heavy-duty fabrics. Chlorinated solvents can provide the necessary adherence without damaging the fabric or affecting the final embroidery outcome.

However, it is essential to use chlorinated solvents in a well-ventilated area and follow proper safety precautions. These solvents can emit strong fumes and should not be inhaled directly. Additionally, they should not come into contact with sewing needles or sewing machine parts, as this can cause damage.

2. Mineral Spirits

Mineral spirits are a commonly used type of embroidery spray adhesive that offers several benefits for embroidery projects. One of the main advantages of mineral spirits is its ability to dissolve adhesive residues, making it ideal for cleaning tools and equipment. This is particularly useful when working with adhesive spray glues. As it helps remove any excess residue that may accumulate on sewing needles or other machine parts.

In addition to its cleaning properties, mineral spirits also serve as an effective embroidery spray adhesive. It can be applied to fabrics or other materials to create a temporary bond. Ensuring that applique pieces or fabric pieces stay in place during the embroidery process. This allows for accurate and precise stitching, resulting in high-quality machine embroidery projects.

When using mineral spirits as an embroidery spray adhesive, it is important to follow proper safety precautions. It should be used in a well-ventilated area to minimize exposure to fumes. Avoid direct inhalation of the fumes and keep the product away from open flames or sparks. Additionally, it is crucial to store mineral spirits in a cool, dry location, away from children and pets.

3. Contact Cement

Contact cement is a powerful adhesive commonly used in embroidery projects to bond fabric pieces together permanently. This versatile adhesive provides several benefits for embroiderers seeking a strong and reliable bond.

When applying contact cement, it is important to ensure that the fabric pieces to be joined are clean and free from any dirt or debris. It is recommended to clean the surfaces with a dry cloth before proceeding. Once the surfaces are clean, a thin layer of contact cement can be applied to both fabric pieces using a brush or a small roller.

One of the key advantages of contact cement is its ability to create a permanent bond between fabric pieces. Unlike temporary adhesives that may lose their grip over time. Contact cement creates a strong and long-lasting bond that can withstand repeated washing and wear.

In addition to its permanent bond, contact cement also offers excellent bonding strength. This is particularly beneficial for embroidery projects where durability is crucial, such as quilting or applique. The strong bond provided by contact cement ensures that fabric pieces stay in place during stitching. Resulting in precise and accurate embroidery designs.

4. Other embroidery spray adhesives

There are several other types of embroidery spray adhesives that can be used for different embroidery projects. These spray adhesives offer a range of uses and benefits, allowing embroiderers to choose the most suitable option for their specific needs.

Another type of embroidery spray adhesive is fabric spray adhesive. This adhesive is specially formulated for use on fabric and provides a strong bond between fabric layers. It is ideal for projects like quilting, where the bond strength is crucial to maintain the integrity of the quilt. Fabric spray adhesive is also versatile and can be used on a wide range of embroidery fabric types.

When using embroidery spray adhesives, it is important to follow the specific instructions provided by the manufacturer. Some adhesives may require shaking before use, while others may need to be applied in a well-ventilated area. It is also recommended to test the adhesive on a small. Inconspicuous area of the fabric before applying it to the entire project to ensure compatibility.

Preparing your Work Area for Applying the Adhesive

Before applying embroidery spray adhesive, it is important to prepare your work area to ensure a successful application.

First, make sure you are working in a well-ventilated area. This will help to minimize the inhalation of any fumes that may be emitted from the spray adhesive. It is also a good idea to lay down a drop cloth or newspaper to protect your work surface from any overspray or drips.

Additionally, ensure that your fabric pieces are clean and free of any dust or debris. You can use a lint roller or a dry cloth to remove any particles from the fabric. By taking these steps to prepare your work area. You can ensure that your embroidery spray adhesive applies smoothly and adheres to the fabric effectively.

Ensuring You Have a Well-Ventilated Area

When using embroidery spray adhesive, it is of utmost importance to ensure that you are working in a well-ventilated area. This is necessary to minimize the inhalation of fumes and to create a safe working environment.

Embroidery spray adhesive contains various chemicals that can release fumes when sprayed. These fumes, if inhaled in excessive amounts, can be harmful to your health. Therefore, it is crucial to take the necessary precautions to protect yourself.

One way to ensure proper ventilation is to work near an open window. This allows fresh air to circulate and dilute any fumes in the workspace. If working in a windowless room, it is advisable to use a fan to help circulate the air.

Additionally, wearing a mask or respirator can provide an extra layer of protection against inhaling the fumes. It is also recommended to wear gloves to prevent any potential skin irritation.

Selecting the Right Type of Embroidery Spray Adhesive

When it comes to embroidery projects, having the right adhesive is essential for achieving professional results. With a wide range of embroidery spray adhesives available in the market. It is important to select the one that best suits your specific needs. Here are some factors to consider when choosing the right type of adhesive for your job and project type.

1. Types of Embroidery Spray Adhesives

There are different types of embroidery spray adhesives available, each offering specific features and applications. From multi-purpose spray adhesive to embroidery spray adhesive and temporary bonding spray adhesive. There is a variety to choose from based on your requirements.

2. Features

Different spray adhesives offer different features. Some adhesives provide a temporary bond, allowing you to reposition fabric pieces before permanently securing them. Others offer strong bonds for machine applique or preparation for quilting. Consider the features you need for your particular project.

3. Applications

Think about the type of fabric you are working with and what you need the adhesive for. Certain embroidery spray adhesives work better on specific fabrics. So it’s important to choose one that is compatible with your project.

4. Quality

Look for high-quality embroidery spray adhesive that is designed specifically for embroidery projects. These adhesives will provide excellent bond strength while being safe for your fabric and embroidery machines.

By considering these factors and choosing the right type of adhesive for your job and project type. You can ensure that your embroidery projects turn out beautifully every time. Whether you need a temporary bond or a strong permanent bond. There is an embroidery spray adhesive out there to meet your needs.

Application of the Adhesive

To ensure a successful embroidery project, proper application of the adhesive is crucial. Follow these steps to achieve the best results.

1. Prepare your work area: Start by clearing a clean and well-ventilated space for your embroidery project. Lay down a protective covering such as a cardboard box or a dry cloth to catch any overspray.

2. Gather necessary supplies: Before applying the adhesive, gather all the required items. This includes the embroidery spray adhesive, fabric pieces, background fabric, and any tools or embellishments you plan to use.

3. Select the right adhesive: Choose an embroidery spray adhesive that is compatible with your fabric and project type. Consider factors such as temporary bonding, bond strength, and repositionability based on your specific needs.

4. Apply the adhesive: Holding the can about 8-12 inches away from the fabric, spray a light and even coat of the adhesive on the back of the fabric pieces you want to attach. Avoid oversaturating the fabric to prevent any potential damage.

5. Attach the fabric pieces: Carefully place the adhesive-coated fabric pieces onto the background fabric or base material. For repositionable adhesives, you have the flexibility to adjust the placement before securing them permanently.

By following these steps and selecting the appropriate embroidery spray adhesive, you can achieve strong bonds and professional-looking embroidery designs. Remember to always read and follow the manufacturer’s instructions for best results.

Conclusion

In conclusion, embroidery spray adhesive is an indispensable tool for embroidery enthusiasts, offering a multitude of benefits for machine embroidery projects. It secures fabric, facilitates precise positioning of applique pieces. And minimizes shifting or puckering, resulting in superior stitch quality. Its versatility makes it suitable for various applications, from embroidery backing to quilting and delicate fabric work. However, it’s crucial to follow manufacturer instructions for safe and effective usage. Ensuring proper ventilation and testing on a small fabric piece.

When selecting an embroidery spray adhesive, consider factors like temporary or permanent bonding, bond strength, and compatibility with your specific project. A well-ventilated workspace is essential to safeguard against fumes. And proper application techniques guarantee professional results. Elevate your embroidery projects with the right embroidery spray adhesive – try our embroidery digitizing services today and experience the next level of precision and quality.

FAQs (Frequently Asked Questions)

Q1. What is the main purpose of embroidery spray adhesive?

Embroidery spray adhesive is primarily used to hold fabric pieces in place during embroidery, ensuring easier stitching and precise positioning of applique pieces.

Q2. What are the benefits of using embroidery spray adhesive in machine embroidery?

Using embroidery spray adhesive reduces hoop marks, improves stitch quality, and prevents shifting or puckering of fabric, enhancing the accuracy of machine embroidery designs.

Q3. What are the different types of embroidery spray adhesives?

There are temporary, permanent, chlorinated solvent-based, and mineral spirits-based embroidery spray adhesives, each offering various bond strengths and applications.

Q4. Why is it crucial to work in a well-ventilated area?

Working in a well-ventilated area minimizes the inhalation of potentially harmful fumes emitted by the adhesive, ensuring a safe working environment.

Q5. What steps should you follow when applying embroidery spray adhesive to fabric?

To apply the adhesive, prepare a clean work area, gather necessary supplies, select the right adhesive, and then spray a light, even coat on the fabric, followed by attaching the fabric pieces to the base material.